Commercial Rooftop Unit (RTU)

This

📘 chapter covers the key functions, components, and applications of Commercial Rooftop UnitsUnit (RTUs)RTU) Overview

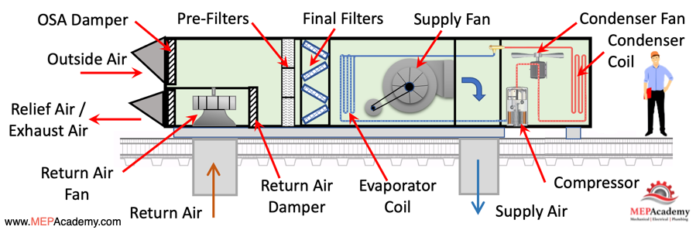

📷 RTU System Diagram

Figure 1: Basic RTU layout showing supply/return air, compressors, and heat exchangers.

🧰 What is a Rooftop Unit?

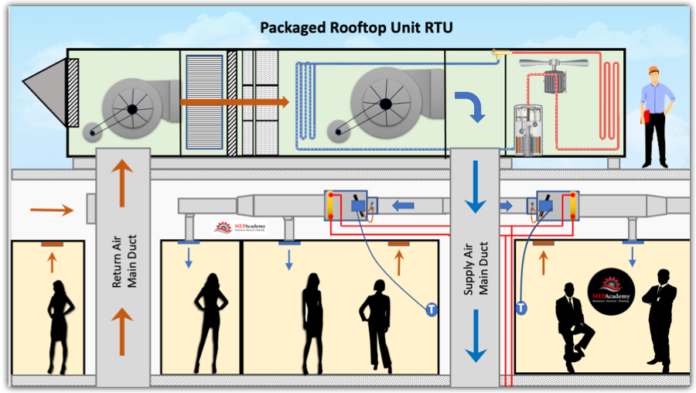

A Rooftop Unit (RTU)—self-contained is a packaged HVAC systemssystem installed on buildingthe rooftops.roof RTUsof are widely used ina commercial settingsbuilding. likeIt retail stores, offices, and schools due to their compact footprint and all-in-onecombines heating, cooling, ventilation, and ventilationair design.distribution into a single cabinet, making it ideal for spaces that lack mechanical rooms.

ReadersRTUs willcondition learn:air and deliver it through ductwork connected from the roof to interior zones.

Used in:

-

HowRetailRTUs operate and distribute conditioned airstores -

Key components: compressors, heat exchangers, supply/exhaust fans, economizersSchools -

TypicalOfficecapacities, voltages, and airflow configurationsbuildings -

Curb installation requirementsGyms andcrane considerationswarehouses

🔧 Key Components

🔹 Cabinet

-

MaintenanceWeatherproof housing for all major components

🔹 Supply & Return Fans

-

Drive airflow through the building’s ductwork

🔹 Compressor & Refrigeration Circuit

-

Provides cooling via a refrigerant cycle

🔹 Gas Furnace or Electric Heat Section

-

Provides space heating

🔹 Economizer (Optional)

-

Allows use of outside air for “free cooling”

🔹 Filters & Dampers

-

Clean air and

servicecontrolaccess best practicesintake/exhaust

Figure:FigureDiagram of2: RTUwithmaintenanceairflow path and key internal componentsaccess.

📏 Typical Specs

-

DesignedTonnage Range: 3 to 60 tons -

Voltage: 208/230V, 460V 3-phase

-

Mounting: Roof curb or rail

-

Airflow: Side or bottom discharge/return

🧱 Installation Considerations

Figure 3: RTU being installed on curb via crane lift.

-

Requires roof curb and structural reinforcement

-

Duct cutouts must match RTU supply/return layout

-

Condensate drain and electrical connections needed

-

Consider local code compliance (curb height, seismic, clearance)

🧼 Maintenance Requirements

Figure 4: Service panel access fortechnicians,quickAPMs,maintenance.and

facilityteams,

✅ includesAdvantages

-

models,All-in-one

andsolutionlinks(heat, cool, ventilate) -

Saves indoor mechanical room space

-

Easy access for service via roof

-

Works well with zone VAV systems

⚠️ Disadvantages

-

Requires crane for installation

-

Exposed to

videoweather—mustwalkthroughsbeofmaintainedRTU -

andLarge

serviceunitsprocedures.mayIt’srequire roof reinforcement -

Not ideal for

fieldmultistoryreferenceduct risers

🛠️ Common Issues

-

Tripped high-pressure switch

-

Dirty condenser coil reducing efficiency

-

Worn fan belts causing poor airflow

-

Economizer failure (stuck damper or sensor fault)

📎 Training & Resources

🧠 Summary

RTUs are versatile, self-contained HVAC systems ideal for commercial buildings needing reliable, rooftop-mounted climate control. They simplify installation, reduce mechanical room needs, and onboardingare newaccessible teamfor members.service—making them a go-to option for many HVAC designs.